Fashion brands need to embrace technology to make it work.

- Judy Kim

- May 28, 2020

- 2 min read

Updated: Jun 1, 2020

Brands have a unique challenge during this time to adapt to our new normal with business disruptions from Covid-19. From the development side, how are you able to conduct operations with teams who make physical product remotely? There need to be an unprecedented method of collaboration digitally both internally and externally in managing product life cycle with suppliers. More than ever, we need to find ways to streamline processes with less time and people. So how do we do all this?

During my time as the VP of design at Macy’s leading private brand I.N.C., I adopted and advocated for emerging technologies early on to streamline processes and encourage digital collaborations to reduce the overall development timeline and minimize sample making waste.

The time is now to re-evaulate how you operate to meet this moment. What ways can you simplify process and improve your speed to market? Although the development process is complex there are simple ways you can improve efficiencies. Here are some tips from my own experiences of success.

Develop new styles from a standard approved and best selling FIT BLOCK. Establish clear spec guidelines that you suppliers can follow. Be open to suggestions from your supplier on how to improve production efficiency on your design up front.

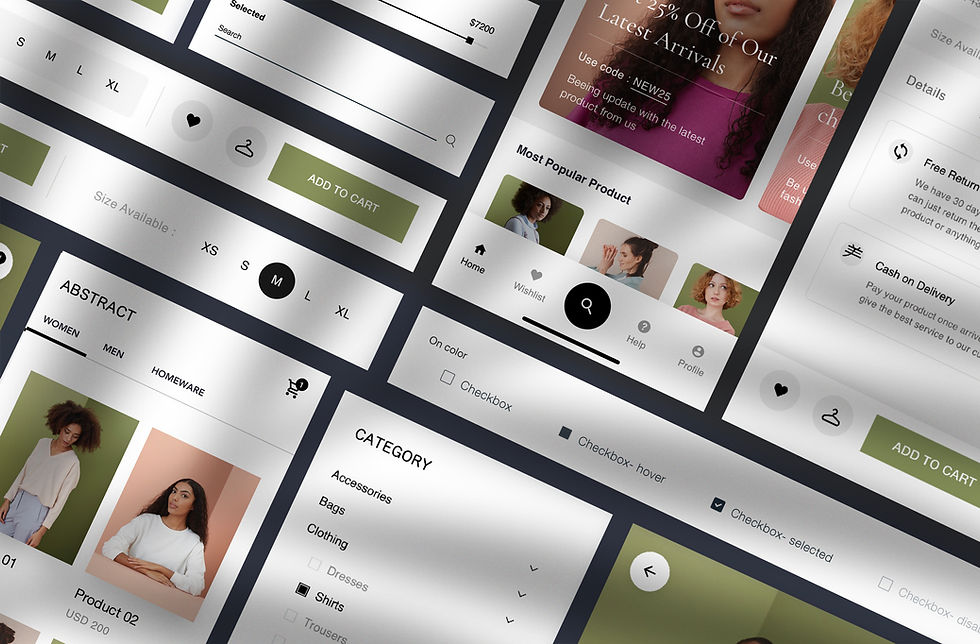

Explore digital development technologies for print/color merchandising approvals. There are several highly regarded companies that offer 3D virtual prototyping. CLO, Turkatech, Optitex are some of the leaders in this technology.

Adopt virtual fitting with your manufactures. Record your fitting and send via video with clear comments and visuals. Less is more. Be as clear in visuals as possible. You can use tools like Vimeo to share videos and get feedback.

Develop a standard PLM system. Big brands usually a sophisticated PLM (product lifecycle management systems) that link up all parties involved in the process of developing a product through the production cycle. For small brands with a small budget, you can use affordable tools like Techpacker or if you really have 0 budget use google share docs to communicate with your vendors on spec/development changes.

Virtual team collaboration tools like Asana, can track and monitor project progress and allow for real time digital collaborations. For designers, it’s really important to have a visual communication platform to get feedback in real time to make design changes. (I really liked using Sway and Yammer to collaborate on creative content with my designers when I was traveling and needed to engage the team to make design decisions)

In summary the key factors to develop a lean and efficient development process will require, adoption of new technologies, open communication with your manufactures, and leveraging virtual team collaboration. Of course, while we still need to see a physical product to make a final decision, these tools and shifts in process can aid the process to optimized. The time is now to leverage all the tools out there to make it work now and improve the overall process for the future and sustainability of the industry.

If you are a brand struggling to navigate how to operate during this disruption, please feel contact me with any questions or comments.

Comments